Generator GPZ-305 - selfrepaired

If the generator of the GPZ305 is defect it is no need to despair! Self repair is not very complex. i have made it myself some years ago with a XT600, but it is identical to every motobike-generator which is running in motor-oil

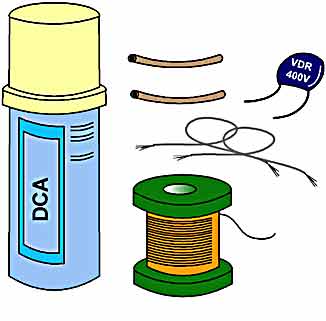

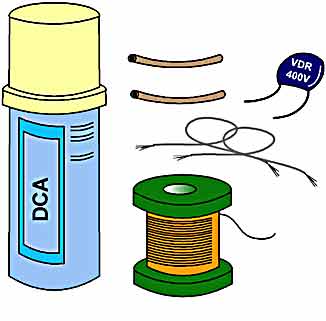

1) What is needed

|

- Silicon-Laquer, hight-temperature and oil-resistant (like DCA200 from Electrolube)

- Magnet wire for extended operable temperature range (>210°C) with suitable diameter. Never take simple magnet wire for transformers. It has an operational range only up 130°C ! If You use the simple magnet wire for transformers (more red isolation), it is not oil-resistant and a little bit cheaper. That is the cause that some engine series like Yamaha XT600 have typical generator failures (shortcut after some years; the manufacturer has saved a little money on the wrong place) The magnet wire for extended operable temperature range is more yellow-golden and the isolation could not be soldered through. This wire is also sometimes defined for military-use.

- Some silicone-pigtail, also high-temperature and oil-resistant

- A little pice of fabric tape and two little peices of insulating tubes

- A Varistor 400v or higher, this is an improvement compared to the original design and saves failures in the future (or an new CDI-box)

|

The price for the material here in Europe is roughly about 30Euro

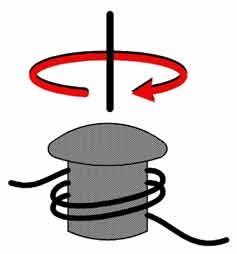

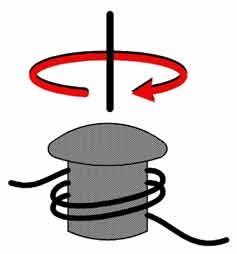

2)Note the winding direction and the thickness on a piece of paper, like on the picture. Then cut and stripp all the windings off the defective coil

|

|

3) Spray the plain coil with Silicone-Laquer, wait some hours and then begin to wind the wire up

Hint: It it not so important that You wind up exactly the same number of windings. Also it is not important if You begin from bottom to top or vice-versa. What counts is the direction: clockwise or anti-clockwise. If You do You a favour try to avoid to much wire-crossings. At a crossing there is quite a lot of mechanical force which can hurt the insulation. Also don't try to conserve silsicone-laquer. The more the better. If the coil seems to look as big as it was before it is enough. But ist is not very important to make exact calculations,. I made the experience that original-manufactured it differs up to 50%

4) After each layer of wire spray another silicone-laquer film

5) If the coil is as thick as it was before, stop and solder two silicone-leads and slide insulating tubes over the slodering points

6) Spray at least a thick silicone-film over it and let it dry a day or more

7) Take mommys kitchen-oven and let it temper for 12 hours at 90°C

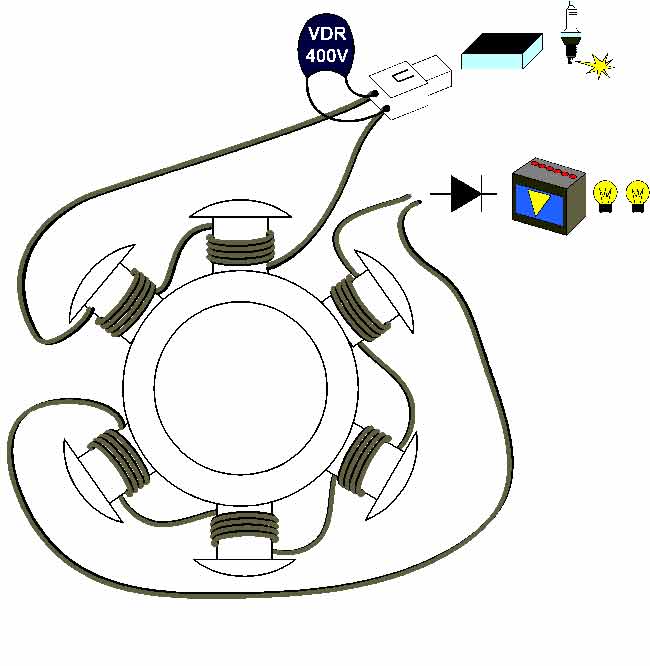

8) After cooling down solder the original cable. If You want do Your a favour solder also the varistor to the cable (see picture). Dont't forget to insulate

9 ) Now the generator is ready for use.